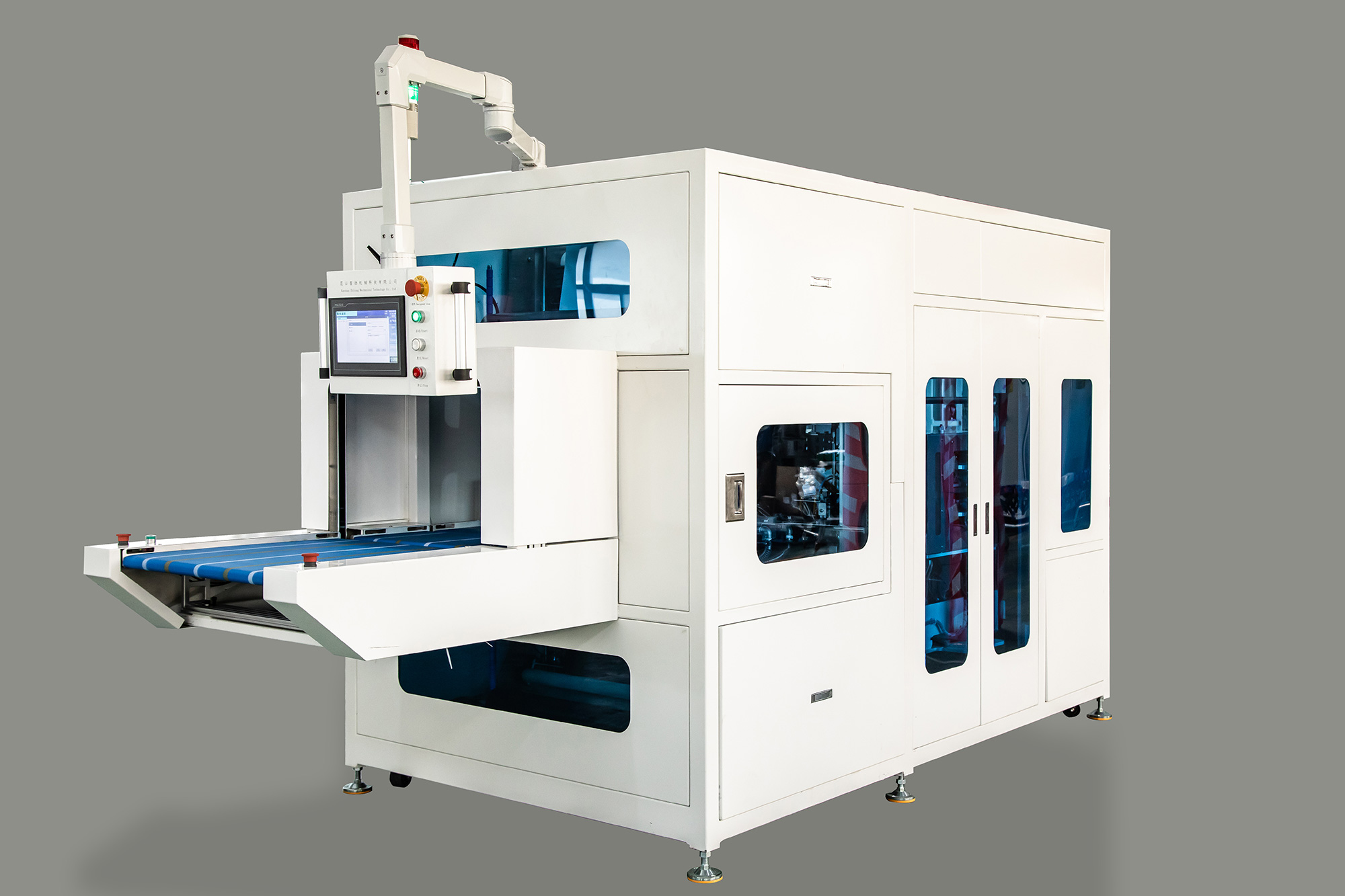

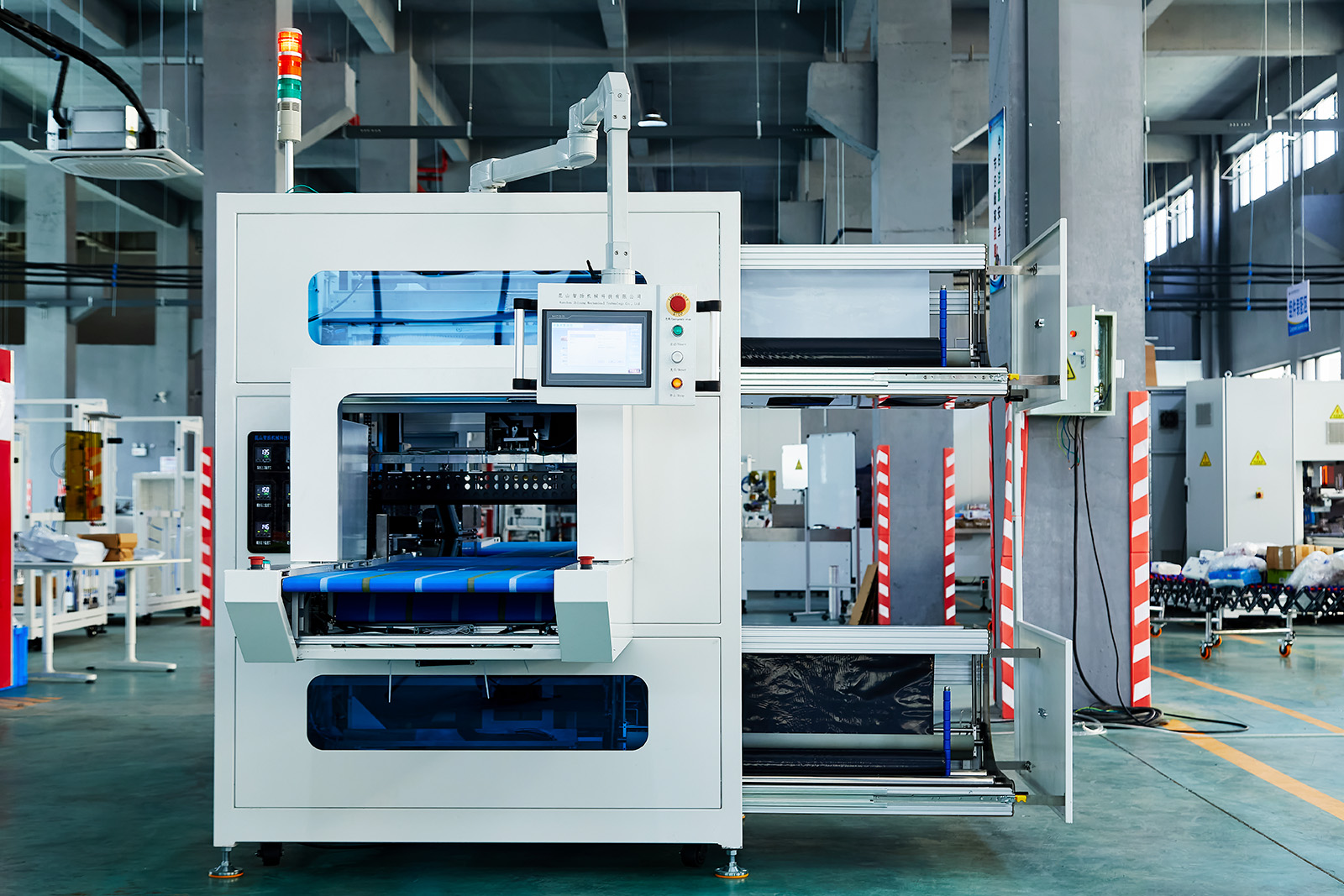

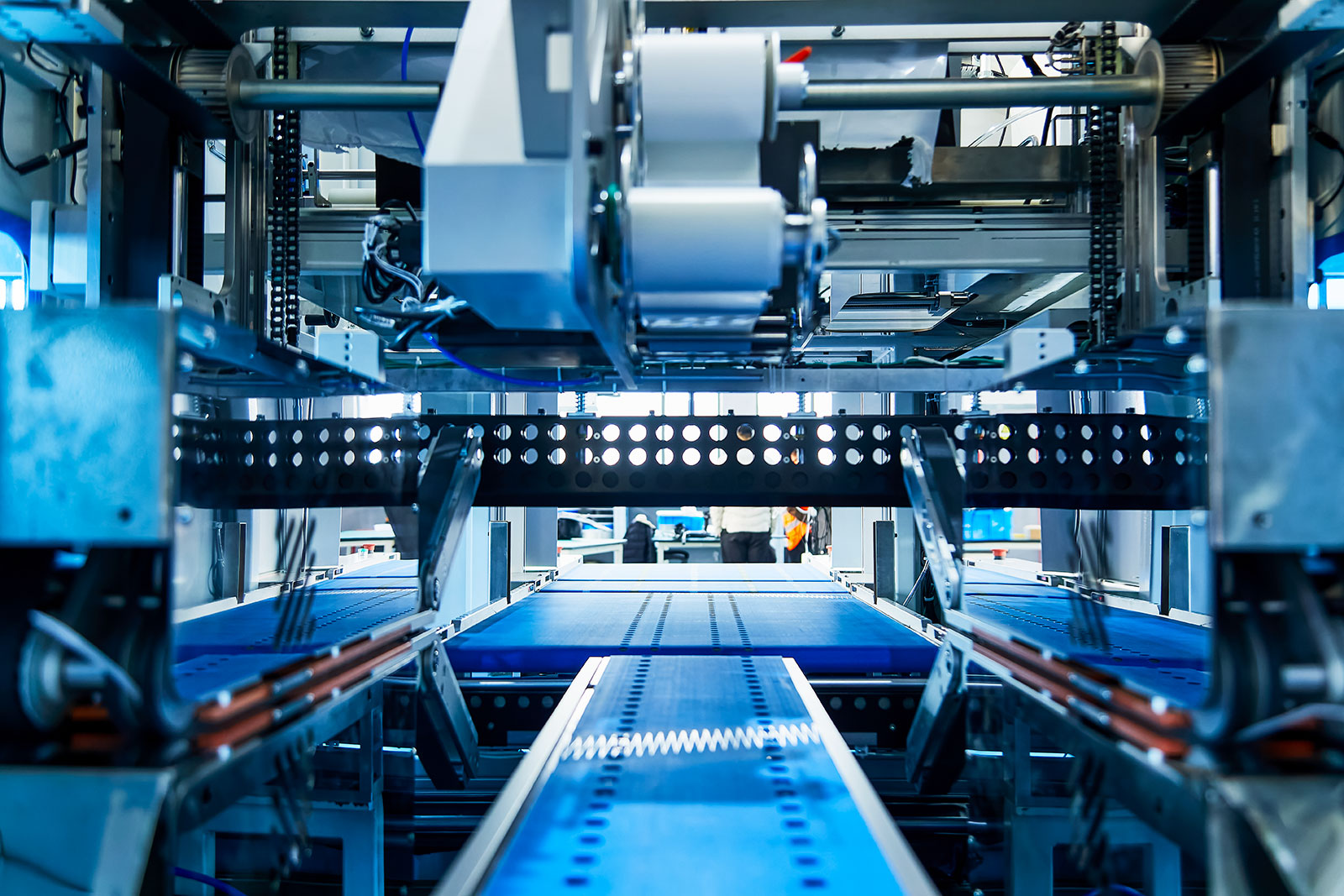

With the rapid development of E-commerce all over the world, online shopping has become a major trend. A book, a T-shirt, a pair of shoes etc., packaging these different size and shape products is a huge challenging for E-commerce logistics. Therefore, we have developed this Intelligent Flexible Bag Packaging Machine as a solution.

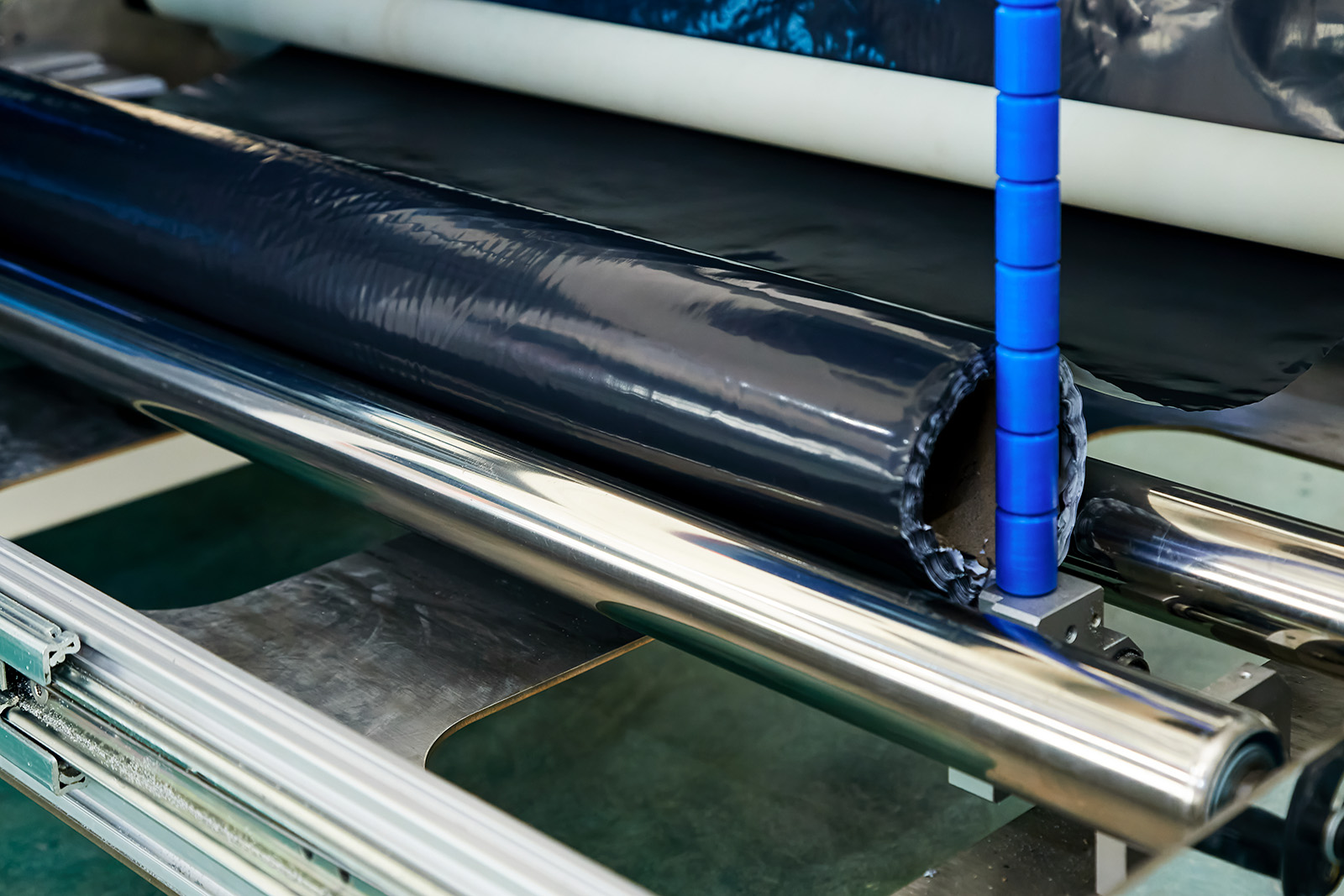

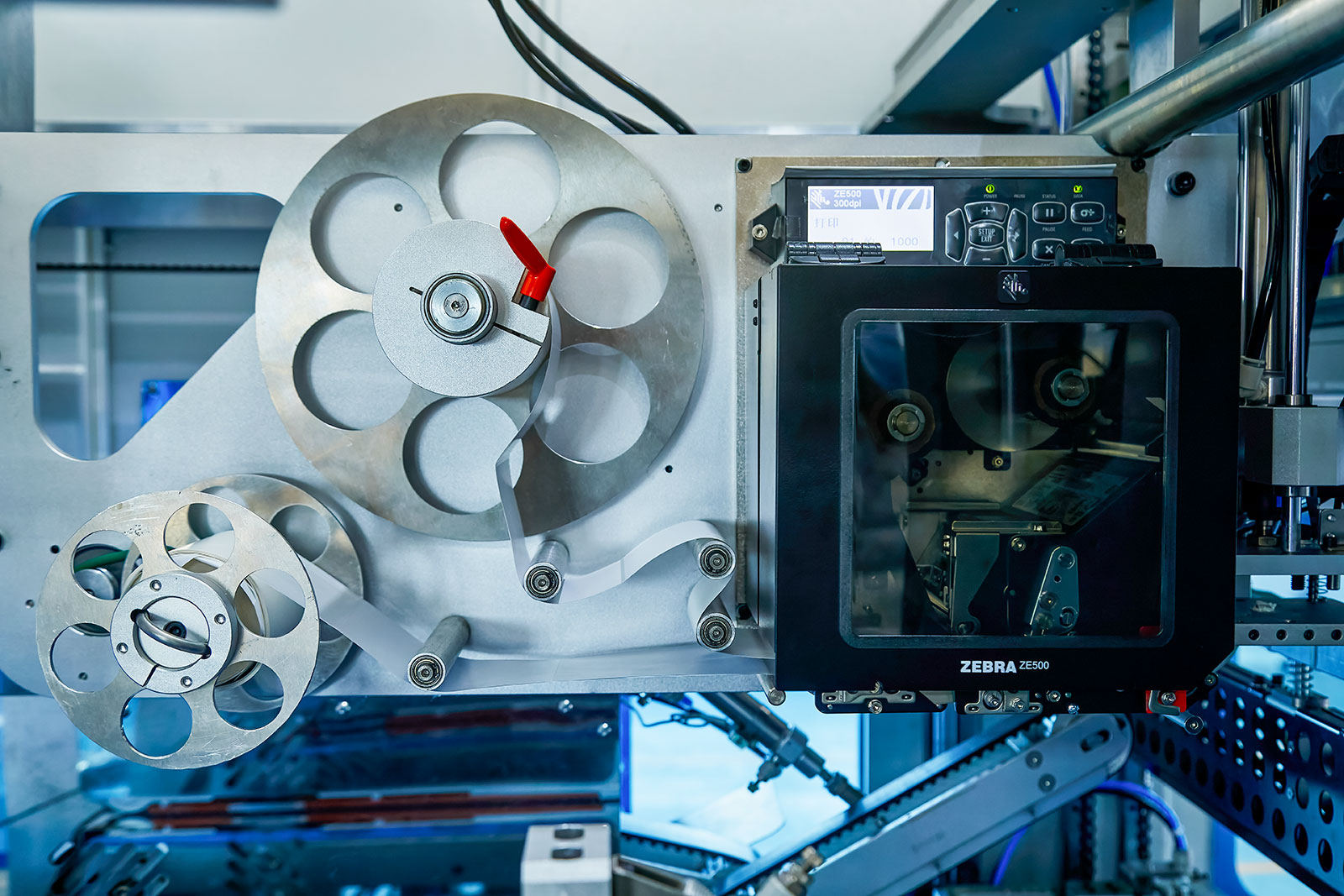

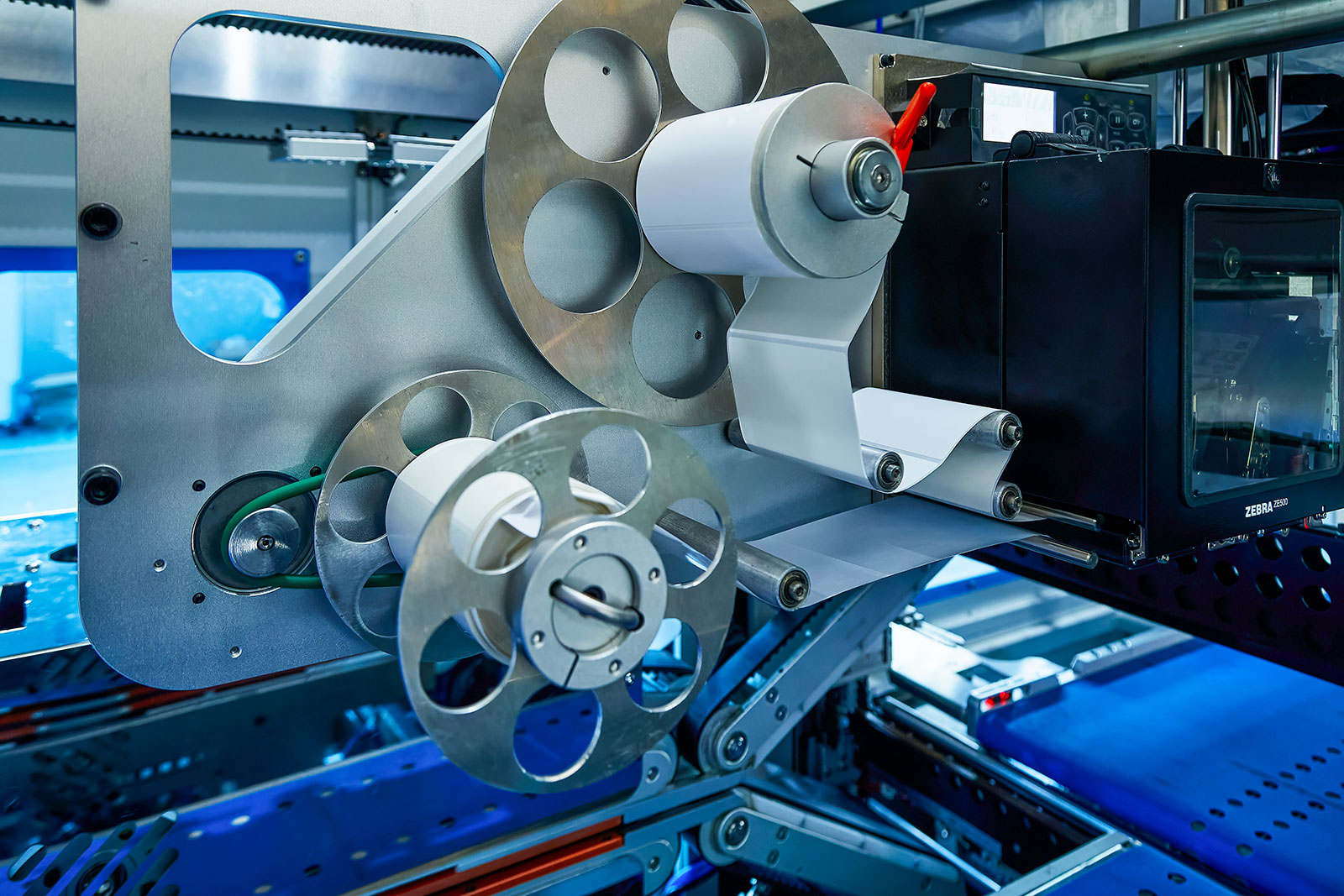

The system consists 4 basic parts: Bar-code Reading, Product Scanning, Packaging, and Labeling Units.